When it comes to ensuring the safety and efficiency of your electrical systems, selecting the right conduit is critical. Rigid PVC conduit is widely used in residential, commercial, and industrial installations due to its durability, corrosion resistance, and ability to protect electrical wiring. However, with so many different types of rigid PVC conduits and fittings on the market, it’s important to make an informed decision to ensure the best performance and compliance with safety standards.

Here we will walk you through the process of choosing the right rigid PVC conduit for your project, covering key factors such as standard compliance, application type, and customization options. By understanding these elements, you can make a choice that meets your needs and adheres to essential industry standards like ETL and UL651.

1. Understand the Standards: ETL and UL651 Compliance

The first step in choosing the right rigid PVC conduit is understanding the standards your conduit must meet. ETL (Electrical Testing Laboratories) and UL651 are two important industry standards that ensure the quality and safety of electrical products.

ETL certification indicates that a product has been tested for compliance with electrical safety standards, ensuring it is safe for use in various electrical applications.

UL651, on the other hand, is the specific standard for PVC conduit and fittings. It governs the design, construction, and performance requirements for rigid PVC electrical conduit, ensuring that it is capable of withstanding environmental factors like moisture, temperature fluctuations, and physical impact.

By selecting ETL-certified rigid PVC conduit, you can be confident that the product meets these rigorous standards, providing long-lasting protection for your electrical wiring.

ETL SCH40 SCH80 Electrical Conduit

2. Determine the Application Type: Residential, Commercial, or Industrial

Next, consider the specific application of your electrical installation. Different environments have varying requirements for electrical protection, and rigid PVC conduit is versatile enough to cater to all types of projects.

● Residential Installations: Rigid PVC conduit is an ideal choice for residential wiring due to its ease of installation and protection from external factors such as water, dirt, and physical damage. You can use it for routing electrical cables in walls, attics, or basements.

● Commercial Installations: In commercial settings, where electrical systems are often more complex, rigid PVC conduit provides strong protection for wiring in environments like office buildings, schools, and shopping malls. It ensures a tidy and safe installation while being resistant to fire and corrosion.

● Industrial Installations: For industrial applications, you may need conduit that can withstand harsher conditions, including exposure to chemicals, high temperatures, and mechanical stress. Rigid PVC conduit offers robust protection and reliability, making it suitable for factories, manufacturing plants, and warehouses.

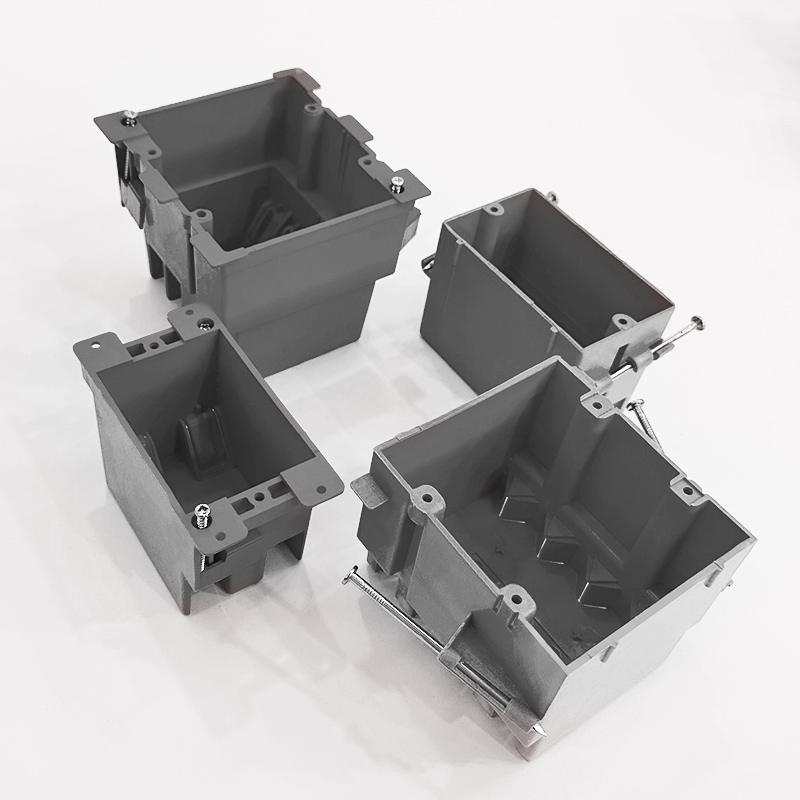

3. Consider the Pipe and Fitting Types

Rigid PVC conduit comes in various types, each suited for specific applications. The most common pipe and fitting types include:

● Schedule 40 & 80 Conduit: These are the most widely used types of rigid PVC conduit. Schedule 40 is ideal for general residential and light commercial applications, while Schedule 80 offers extra thickness for more demanding environments, including industrial and heavy-duty uses. Both types are available in a range of sizes to suit different wiring needs.

● DB60, DB100, and DB120 Conduit: These specialized types of conduit are used in certain industrial applications where specific environmental conditions, such as exposure to high heat or chemicals, may require extra protection. DB series conduit is designed to offer superior durability in more demanding environments.

● Type A and Type EB Conduit: These are specific configurations of PVC conduit used for different types of installations. Type A is generally used for above-ground applications, while Type EB is commonly used for underground installations where greater protection is required.

By selecting the appropriate pipe and fitting type for your project, you ensure that the conduit meets the necessary durability and protection standards for your specific environment.

4. Size Matters: Choose the Right Size for Your Project

Choosing the correct size of rigid PVC conduit is essential to ensuring that your electrical wiring is properly protected and that the system remains efficient. Conduit size depends on the number and type of wires you need to run through the conduit.

● For Residential Projects: Smaller sizes (1/2 inch to 2 inches) are typically sufficient for residential applications, where fewer wires need to be routed.

● For Commercial and Industrial Projects: Larger conduit sizes (2.5 inches to 4 inches) may be necessary, especially in environments with more complex electrical systems and where the conduit needs to accommodate multiple wires or larger gauge cables.

It’s crucial to account for the total number of wires, their gauge, and any future expansions. Overcrowding the conduit can lead to overheating and potential system failure.

5. Customization Options: OEM/ODM Solutions

In some cases, you may need specific customization options to meet the exact needs of your project. Customization allows you to tailor the size, color, and packaging of the rigid PVC conduit and fittings to align with your project’s requirements.

● Size Customization: If the standard sizes do not meet your needs, many manufacturers offer flexible OEM/ODM options that allow you to customize the conduit dimensions to fit your installation requirements perfectly.

● Color Customization: In some environments, especially in commercial or industrial settings, you may need color-coded conduit for better organization or to meet specific aesthetic preferences. Customized color options are available for certain types of PVC conduit.

● Packaging Solutions: Custom packaging options can help streamline logistics and ensure the product is delivered in a way that suits your project’s needs, whether it’s for easy handling, storage, or transportation.

By opting for a manufacturer that offers flexible OEM/ODM rigid PVC solutions, you can get the exact conduit and fittings needed for your project.

6. Durability and Longevity: Why ETL Rigid PVC Conduit is a Smart Choice?

One of the key advantages of ETL-certified rigid PVC conduit is its durability. Rigid PVC is naturally resistant to corrosion, making it ideal for use in outdoor or humid environments. Additionally, it is non-combustible, providing an added layer of fire safety for electrical systems. Rigid PVC conduit is also highly impact-resistant, which protects your wiring from damage in high-traffic or industrial environments.

The longevity of ETL rigid PVC conduit ensures that your electrical systems remain protected for many years, reducing the need for frequent replacements and minimizing maintenance costs.

PVC Electrical Conduits and Fittings Manufacturer

7. Cost-Effectiveness

While rigid PVC conduit may have a higher initial cost than some other materials, its long-term durability and low maintenance requirements make it a cost-effective choice in the long run. Whether for residential, commercial, or industrial applications, ETL rigid PVC conduit provides a reliable and economical solution for electrical wiring protection.

Conclusion

Choosing the right rigid PVC conduit for your project is essential for ensuring the safety, efficiency, and longevity of your electrical system. By understanding the key factors like standards compliance (ETL and UL651), application types, conduit sizes, and customization options, you can select the best solution for your needs.

ETL rigid PVC conduit offers reliable protection and is available in a wide range of sizes and types to suit any installation. Whether you're working on a residential project or a large industrial installation, ETL Depot is your trusted partner for professional-grade electrical solutions. Contact us for more information about OEM/ODM rigid PVC conduit solutions.